ROSS Engineering | Modular Balcony Install, Dublin

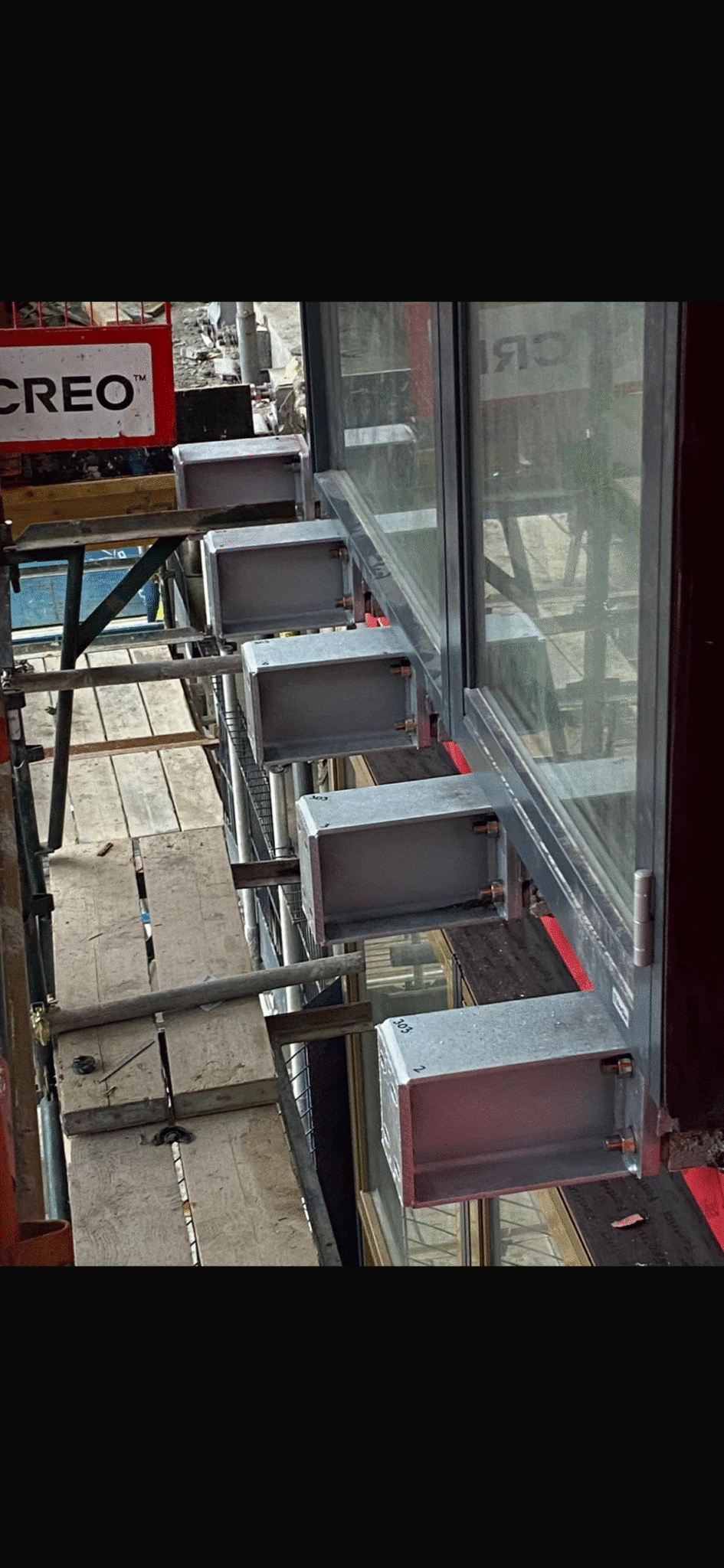

A key challenge emerged during the early stages of installation: the balcony Schöck elements, installed by a third party, had been positioned incorrectly. This presented a major structural issue that could have led to costly delays. Rather than halt progress, our team quickly assessed the situation and proposed a bespoke solution. We designed and fabricated custom balcony stubs to adapt to the misaligned Schöck, ensuring structural integrity without requiring reinstallation or remedial works.

This solution was made possible by the close collaboration between our Survey and Detailing Teams, who worked in parallel to resolve the issue.

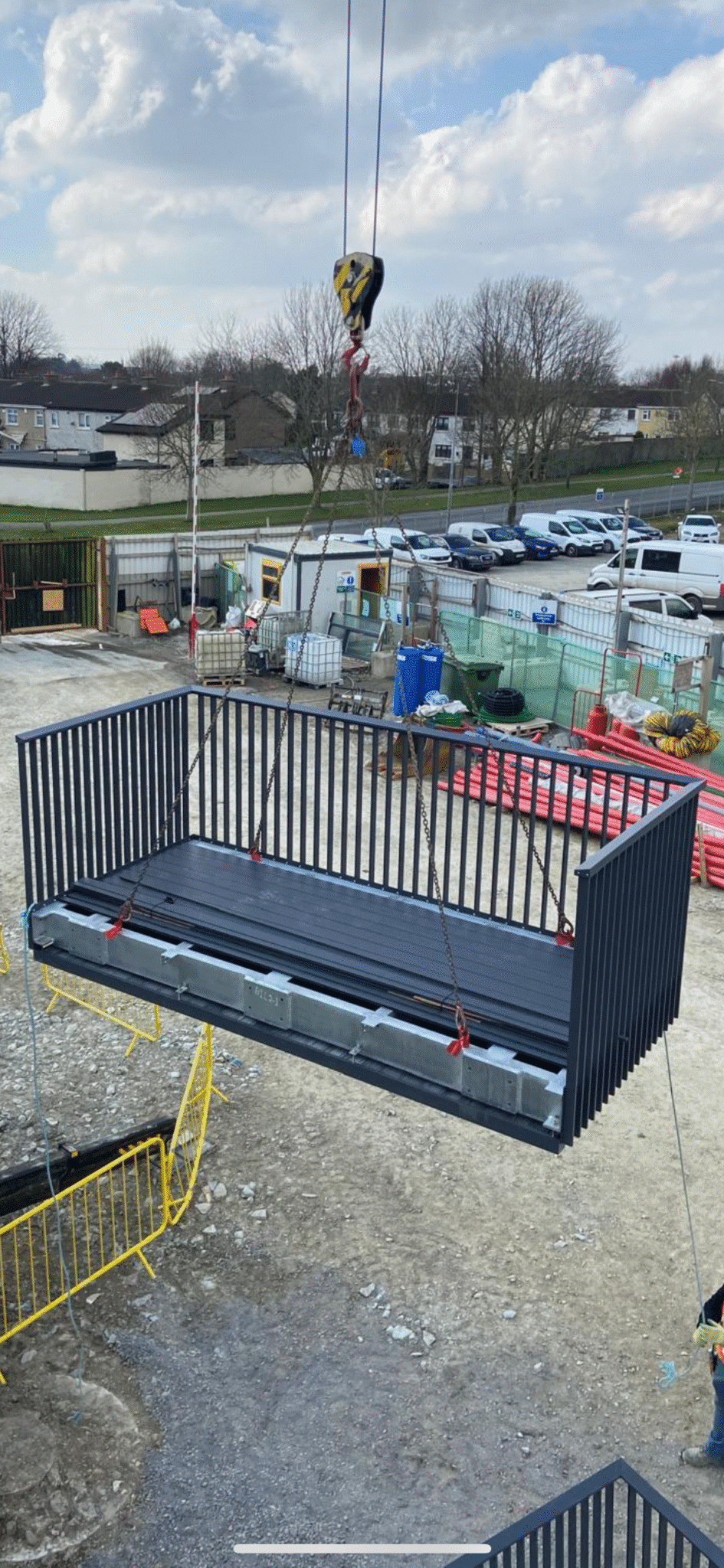

Thanks to the combined efforts of our detailers, fabricators, and welders, we turned around the tailored solution rapidly. The team’s ability to react swiftly to unforeseen problems and deliver practical fixes was crucial to maintaining the project schedule. By handling all fabrication in-house, we retained full QA/QC control at every stage. This ensured each balcony met our quality standards before leaving our facility, resulting in a smooth, efficient installation on site.

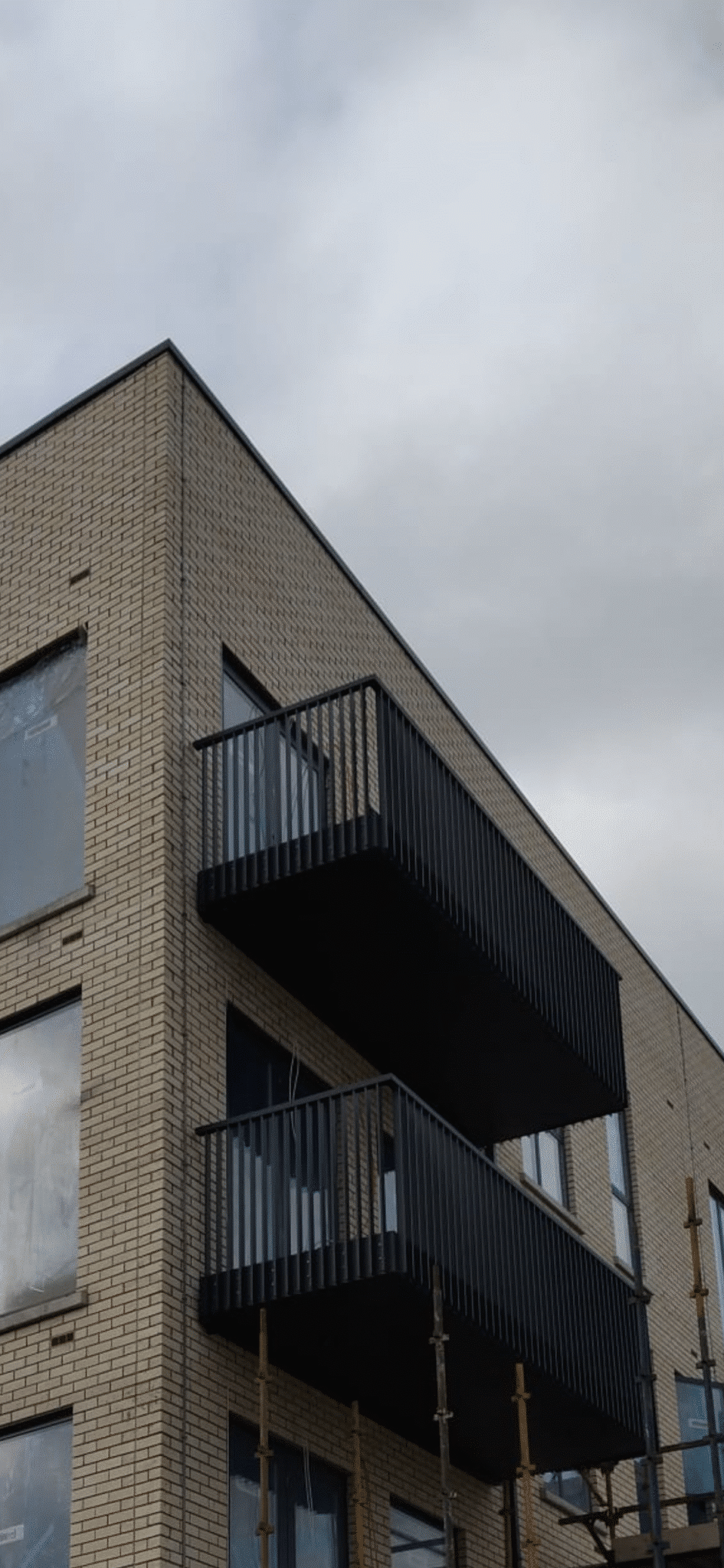

In the end, we met the client’s tight deadlines while adding value through practical problem-solving and cost-saving innovation—demonstrating the strength and flexibility of our offsite manufacturing model.

This project deserves an Irish Steel Award for its demonstration of innovation, efficiency, and excellence in steel fabrication under pressure. Faced with a challenging brief to deliver 125 balconies within a tight timeframe for a high-profile residential development in Dublin city, our team delivered a full service solution that showcased the strength of Irish steelwork, but more importantly, collaborative team work!

All balcony bases and cantilever stubs were fabricated and pre-assembled at our offsite manufacturing facility in Roscommon. This in-house approach enabled us to maintain full control over production, adhere to strict QA/QC protocols, and significantly accelerate delivery. It also minimized on site disruption, which was crucial given the urban location and tight site logistics.

The seamless collaboration between our steel detailers, fabricators, and welders meant we could respond quickly to challenges, delivering tailored solutions without compromising on safety or quality. The success of this project highlights the importance of flexible, responsive steelwork partners who can think creatively under pressure.

Through precision fabrication, excellent project management, and innovative problem- solving, this project exemplifies the best of Irish steelwork. It reflects not only technical capability but also adaptability, efficiency, and a commitment to delivering exceptional results in complex conditions.