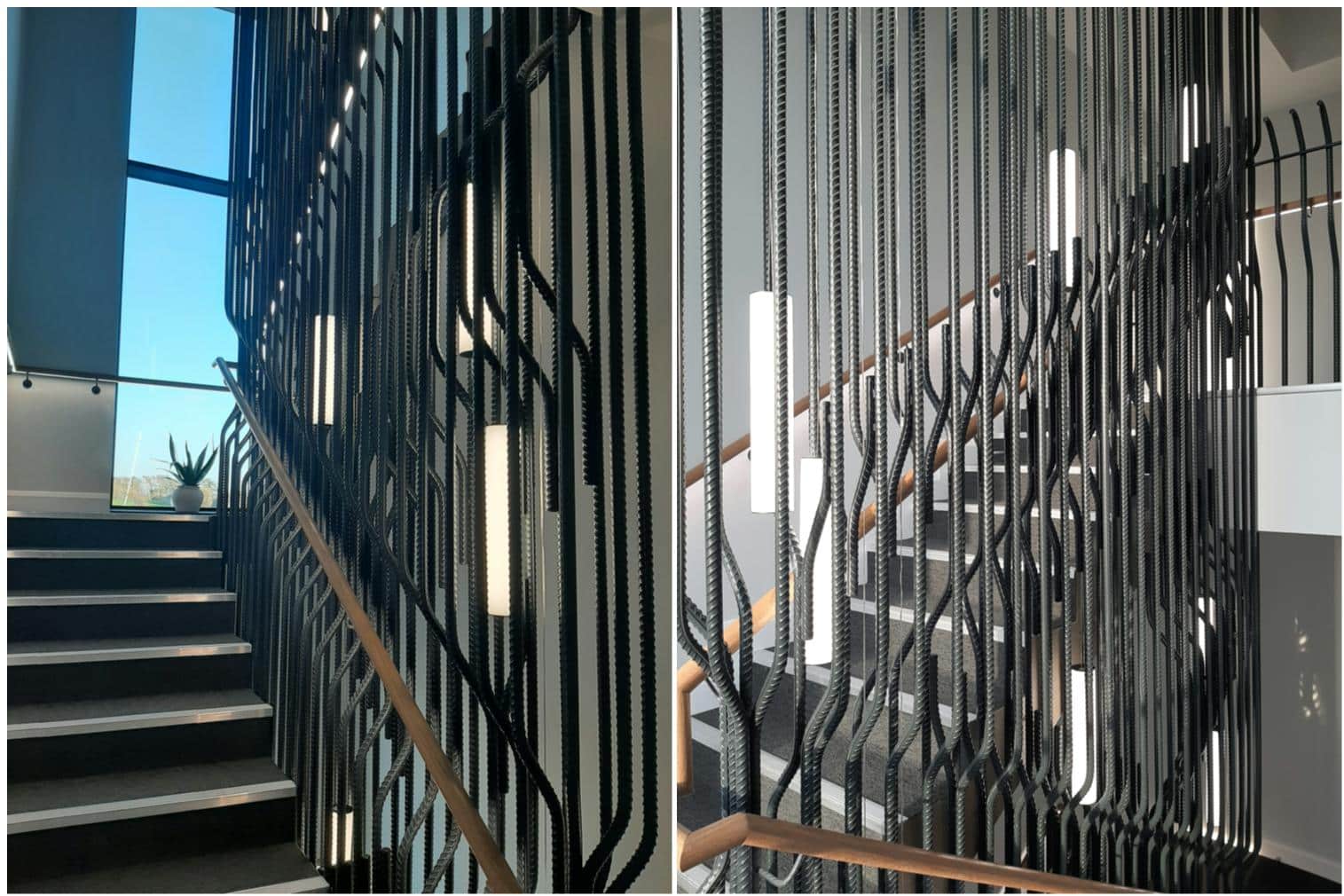

Midland Steel Supplies (FasterFix) | Portlaoise Smart Factory (PSFA) "Pipe Organ Staircase"

The Pipe Organ Staircase represents a bold and unprecedented reimagining of architectural reinforcement—executed with exceptional precision and intent.

Located within a highly constrained staircore, the project features the continuous integration of 25mm high-yield reinforcement steel across three building levels. Uniquely, this was achieved without any splices, welds, or mechanical couplers, instead using recessed dowel joints. The result is both a landmark structural solution and a powerful visual centrepiece.

Inspired by the vertical rhythm and sculptural grandeur of a pipe organ, the staircase transforms traditional reinforcement into expressive architecture. Each vertical bar is intentionally left exposed, rising uninterrupted through the staircore in a dramatic, elegant formation. This challenges conventional thinking, reimagining reinforcement steel not as a hidden utility but as the primary design language.

Every bar was bent, aligned, and modelled with millimetre precision using 3D tools. Structural detailing was completed in Tekla Structures, architectural modelling in Revit (via in-place modelling), and multidisciplinary coordination managed through IFC models. This high-resolution, digital model-to-field workflow enabled full bar-by-bar validation—spacing, cover zones, clearances, and bends—well before fabrication.

The steel was treated with a transparent anti-corrosion finish to preserve its raw aesthetic while ensuring long-term durability. Integrated pendant lighting enhances the upward flow, echoing the organ motif. Even the bespoke steel handrail brackets were developed in-house to allow for a continuous LED strip within the solid oak handrail, providing both illumination and seamless fixing.

Fabrication was carried out off-site at Midland Steel’s Mountmellick plant using custom-built jigs. Each component was digitally validated and mock-tested before delivery. With zero tolerance for installation error, bespoke rigging methods and tight sequencing allowed safe, accurate threading of the bars through slab penetrations on a live construction site. Custom timber supports were used to guide and tie bars during phased vertical installation.

What truly distinguishes this staircase is the seamless integration across disciplines—architecture, engineering, digital detailing, fabrication, and installation—all managed in-house under Midland Steel’s fully integrated delivery model. It stands as a rare achievement in architectural and structural innovation, redefining how reinforcement can perform both structurally and sculpturally within a space.

All inhouse Midland Steel works, lead entirely by Connie Shiel, Architectural Technician, BIM Specialistand musician.

This project merits recognition for its groundbreaking design and exceptional functionality. The innovative use of bold 25mm high-yield reinforcement steel within an exceptionally constrained staircore pushes the boundaries of structural engineering and architectural metalwork. Seamlessly integrating advanced BIM coordination (Revit, IFC, Tekla) with precision fabrication and installation, the staircase not only meets stringent building regulations but also delivers a refined architectural expression.

Its holistic in-house delivery under a single design lead ensured unparalleled quality control and alignment between structural performance and aesthetic intent, setting a new industry standard for design-led, functional metalwork in complex architectural environments.

The staircase not only meets stringent building regulations but also elevates architectural expression, setting a new industry benchmark for design-led reinforcement delivery in complex environments.