Hayes Mechanical & Engineering | B2 Heat Pump Upgrade, Manufacturing Plant Dublin

The strategic partnership between Hayes Mechanical & Engineering (HME) and the global biopharmaceutical company Ipsen is a clear case study in how a relationship built on a peer-to-peer dynamic, rather than traditional hierarchy, leads to elevated trust and responsibility. Our journey with Ipsen began in 2021, and through a collaborative culture and a

consistent, high-quality delivery of work, we evolved from a specialized subcontractor into a trusted main contractor at Ipsen’s highly regulated Dublin pharmaceutical facility. This was not a standard client-vendor relationship; it was a partnership from the start, focused on achieving shared goals.

The evolution of this partnership is charted through a portfolio of successfully executed projects. Our initial engagements were not simply tasks we were assigned, but collaborative efforts that provided a platform to demonstrate our value within a live and sensitive manufacturing environment. Projects such as “The Chiller Project”, the “Generator Project” all involved intricate mechanical and piping installations in critical areas of the plant. By delivering this foundational work safely, efficiently, and in close collaboration with our Ipsen counterparts, we established a baseline of operational trust and proved ourselves to be reliable partners.

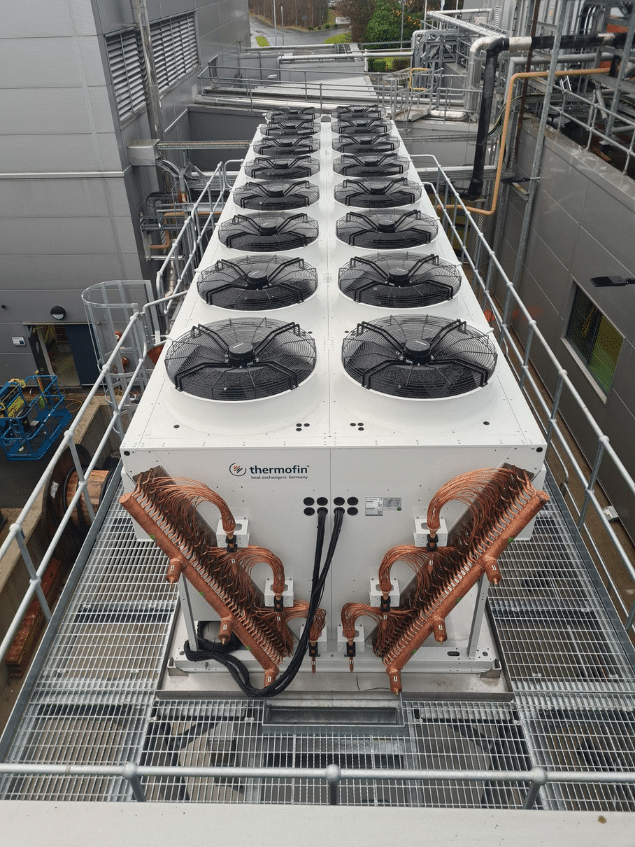

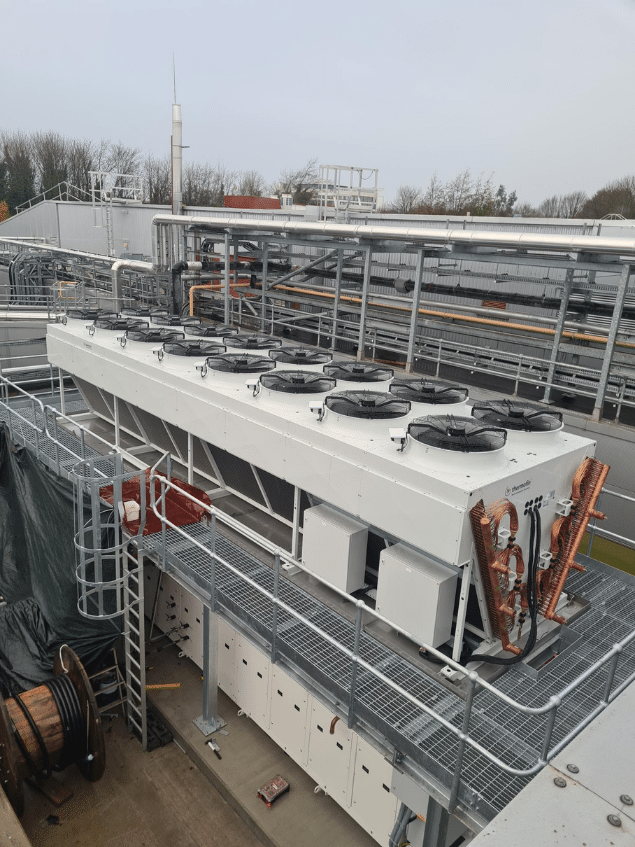

This initial success naturally led to engagements of greater scale and complexity, which marked our transition to the role of main contractor and Project Supervisor for the Construction Stage (PSCS). The “B2 Heat Pump Upgrade” was a pivotal project where we first took on the PSCS responsibilities.

This major infrastructure upgrade required deep collaboration to ensure minimal disruption to Ipsen’s ongoing operations, and its success, formally recognized in a glowing testimonial from Ipsen’s Engineering & EHS Director, was a testament to our integrated team approach. Since the successful delivery of the heat pump project, we have been appointed as the PSCS on all subsequent projects.

In conclusion, our progression at the Ipsen facility was the direct result of a relentless focus on performance and a truly collaborative partnership. We worked alongside Ipsen, as peers with a shared objective. By consistently delivering fine work on projects of increasing importance, we solidified a partnership where we now lead critical projects in one of the world’s most demanding industries.

This project is a strong contender for an award due to Hayes Mechanical & Engineering’s proven ability to deliver critical infrastructure upgrades with exceptional professionalism, minimal operational impact, and unwavering commitment to client satisfaction and safety.

The direct testimonial from Fabien Eschbach, Ipsen’s Engineering & EHS Director, is a powerful endorsement of this project’s success. He explicitly praises Hayes Mechanical’s “high level of professionalism, technical competence, and a strong commitment to quality and safety.” This feedback is invaluable as it comes from the client directly impacted by the work. Furthermore, the project’s execution ensured minimal disruption to a live pharmaceutical manufacturing facility, which is a significant achievement given the inherent complexities and stringent requirements of such environments. The focus on efficiency and meeting “all performance and compliance expectations” demonstrates a comprehensive understanding of the client’s needs and industry standards.

The fact that this project led to Hayes Mechanical becoming a “trusted partner” for Ipsen and securing “additional projects on site” speaks volumes about the sustained quality and reliability of their work. This ongoing relationship is a clear indicator of long-term client value and trust built on successful project delivery.