Hayes Mechanical and Engineering | St Vincent’s University Hospital – Block N Boiler House Mechanical Services Upgrade

St Vincent’s University Hospital – Block N Boiler House Upgrade

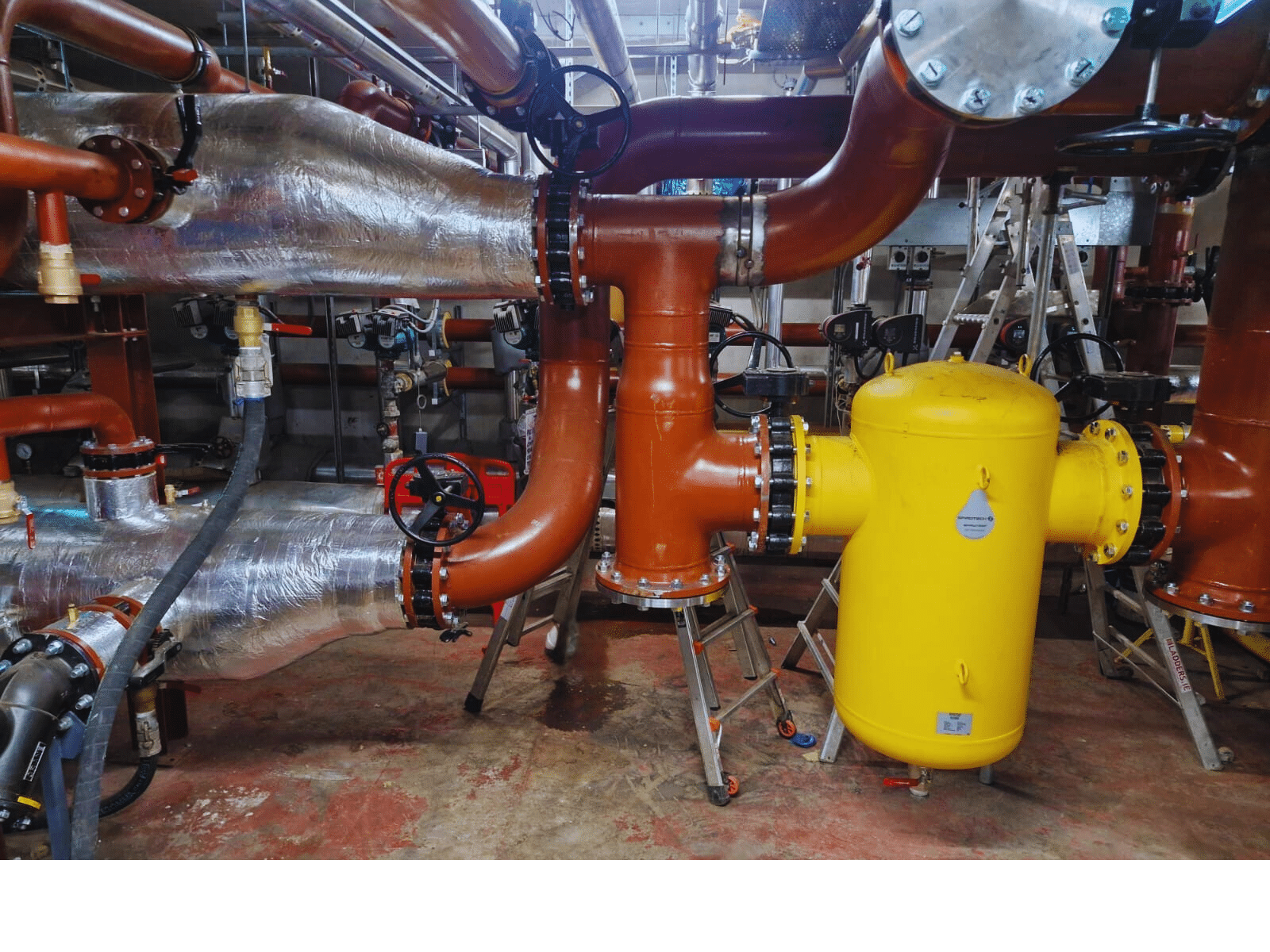

This project formed part of Call-Off 3 of the enabling works for St Vincent’s University Hospital, focusing on the full mechanical services upgrade of the Block N Boiler House. Hayes Mechanical & Engineering was appointed to model, prefabricate, and install key pipework systems—including Low Pressure Hot Water, Domestic Hot Water, and gas lines—within a live, high-risk hospital environment.

The hospital remained fully operational throughout, requiring zero service disruption, contamination, or downtime. To meet this challenge, Hayes Mechanical implemented a LEAN prefabrication strategy, using BIM-coordinated models to fabricate pipework offsite. This reduced installation time, minimised onsite welding, and enhanced safety in a congested setting.

Over 1,800 linear metres of Sch 20 carbon steel pipe (DN15 to DN500) were fabricated and installed.

Major assemblies included:

- Reoriented primary boiler header

- Three plantroom distribution circuits

- Gas line extensions and gas skids

- Pump and plate heat exchanger (PHE) skids

- Live tie-ins to existing AHUs and risers

Prefabricated sections—flanged pipework, valves, and supports—were manufactured in-house and installed during scheduled time windows, coordinated with SVUH’s maintenance teams.

Installation followed EN 1090-2 execution standards using CE-marked materials. All welding was completed by coded personnel, with NDT performed on 10% of all welds.

Where live tie-ins were needed, pipe freezing and hot tapping methods ensured uninterrupted services.

Phased works included the removal of calorifiers, relocation of plant, and installation of new boosters and PHEs. All pipework was pressure-tested, labelled, and reconnected following sterilisation protocols.

Commencing in March 2025, the project remains on schedule through October 2025, with zero unplanned downtime—achieved despite the constraints of working within a live clinical environment.

This project showcases Irish engineering excellence in pipe fabrication and installation under uniquely demanding conditions. Hayes Mechanical & Engineering delivered a complex, multi-phase mechanical upgrade without disrupting services at a fully operational hospital. Every aspect of this project reflects quality, innovation, and resilience.

Our approach was guided by precision and discipline:

• LEAN prefabrication minimised on-site work and enhanced safety.

• BIM-driven workflows ensured seamless coordination across all services.

• Millimetre-tolerance installations enabled integration with legacy systems.

• No unplanned service outages—a critical achievement in healthcare settings.

We overcame challenges including strict lifting restrictions, confined access routes, and the need to maintain uninterrupted power and service to live hospital systems.

Our planning and sequencing enabled clinical continuity and a snag-free commissioning process. The quality and reliability of our work reinforced our reputation as a trusted partner for complex

healthcare environments.

This project should be recognised for its:

• Technical achievement under pressure

• Commitment to safety and quality

• Collaborative integration with design, construction, and hospital stakeholders